I remember the days in a small Minnesota print shop, when I guessed at color by number of parts (Note, a part is actually a percentage of total weight) and mixed them up on a slab of granite. I used a razor blade to draw down the color and compare to the book. Soon the “by guess” and “by golly” method changed to include a scale and a “quick peek,” which was a small rubber roller that would apply a measured amount of ink to the paper for a closer color match. Not very scientific but it worked.

How to Mix Colors

For point of reference, an easy color to mix is PMS 185 – the build of 185 is 75% Rubine and 25% Yellow.

How to mix??

- First, you will need an ink knife, sort of a longer putty knife, and a hard surface like glass or stainless steel.

- Then, determine how much ink you need (that is a different story for another blog). Let’s say two pounds.

- Multiply 2 by .75 = 1.5 lbs. of Rubine Red (75% Rubine)

- Weigh out 1.5 lbs. or Rubine red and put this on the mixing surface

- Multiply 2 by .25 = .5 Yellow (25% Yellow)

- Weigh out .25 lbs. mixing yellow and put on the mixing surface

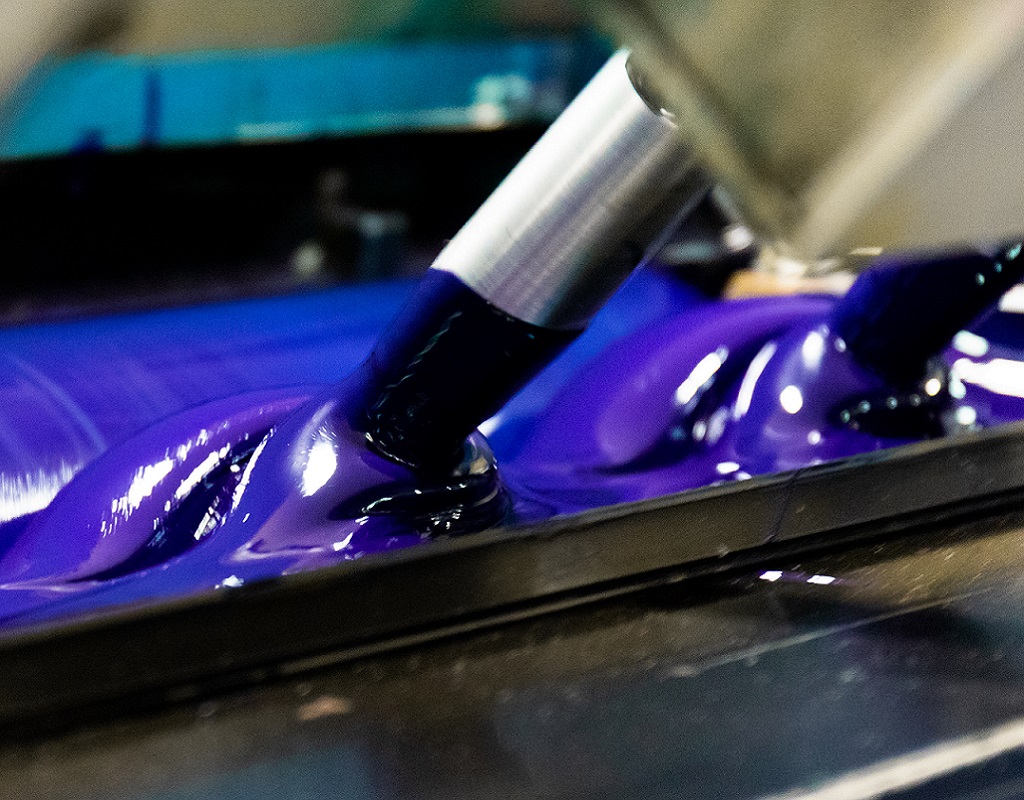

Just as in the old days you can put your ink on glass or granite or other smooth surface and mix them together. On a larger scale these colors would be mixed on a machine.

Do watch out for the comedian mixing up warm red!! See explanation below…

- Once thoroughly mixed take a sample and draw it down on your paper and compare it to the PMS guide. Note: colors change as they dry, use a hair dryer or hot air gun to speed up the process, if you are mixing up UV ink you will need a light source.

- Also, you must use the right matching guides to match your mixture. Formula Guides are based on the paper you are using coated or uncoated. Important note: Paper makes a big difference when matching color. Make sure you are drawing down the ink on the same paper you are going to be printing on..

Color Matching

If you are comfortable matching with your eyes, and the color looks good, you are good to go. The light in the area where you are reviewing color does make a difference. Are you viewing in 5k light? 5000 Kelvin light is the industry standard for viewing color.

Even though color has become more of a science with processes and standards, one can still weigh out small batches and mix them on a table and get relatively close.

Your ink company has become the expert with all the tools and standards for consistent larger batches of PMS spot colors. They will provide you will a drawdown of the color on the paper you are going to print on and provide spectral analysis if requested. (Some clients insist on the LAB having a Delta E of +/- .02), and for good reason. Corporate branding is expensive to achieve and maintain for immediate brand recognition.

If you need more high-tech color matching, request a drawdown from your printer and ask for LAB print out to accompany it. (What is LAB? Check out X-rite blog).

If you know the spectral specifications for your color and you have a spectrophotometer, you can check your LAB, or you can compare the LAB number to the book (or your swatch) and then get an LAB +/-, which is also known as Delta E. Here is a great link about LAB and Delta E.

About Pantone

Around 1963, The Pantone (PMS) concept came along to help printers mix a color that would match if it were mixed in New York or California or any other state.

Originally, Pantone colors were mixed using a set of 11 base colors to achieve 500 colors and used a numeric system to identify them.

Now, 14 basic colors are used as the building blocks that grew in to 1,114 available colors in the formula guide.

Base colors include Yellow, Warm Red, Rubine Red, Rhodamine Red, Purple, Violet, Process Blue, Reflex Blue, Green, Black and Transparent White (clear), Yellow 012, Orange 021, Blue 072 and Red 032.

Speaking of high-tech, Pantone now provides RGB, HEX and CMYK equivalent values for each color. You can look up PMS colors like 185 on their Pantone Web Site.

In 2007 Pantone and Xrite teamed up to become one company.

The new color guide with additional colors has 1,755 solid color choices.

There are other colors that can be used such as florescent or metallic inks; however, the standard color matching guides or PMS colors are the starting point and base of the main color matching system.

Pantone recommends changing your formula guide annually as paper can yellow and color can fade.

Nahan’s In-House Ink Company, INX

Nahan Printing has an in-house ink company called INX. They are industry-leading experts in color consistency and creativity. This allows Nahan to build custom mixed colors on site, provide quick turn drawdowns to customers, and create an ink mix that matches across all of our presses. This helps to maintain color consistency across components and help maintain brand standards.

The HOT INK TRICK is an old spoof. As the press comedian is mixing ink on the slab, an office person (You) walks up and asks what you are doing? (S)He will respond: Mixing warm red, it gets real hot when I mix it. Want to feel? So you put your hand near the ink and the press comedian slaps your hand in to the ink…The old hot ink trick is not very funny 🙂

(Stay tuned for more printing inside jokes….perhaps next time I can fill you in on the paper stretcher or the dot gain. We usually keep them in the basement).